-

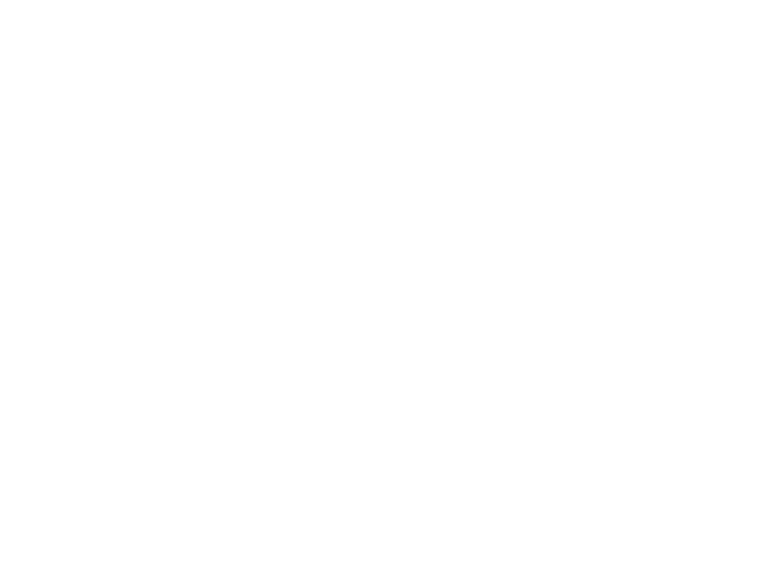

7/29/08 - A view of the plans from CLC.

-

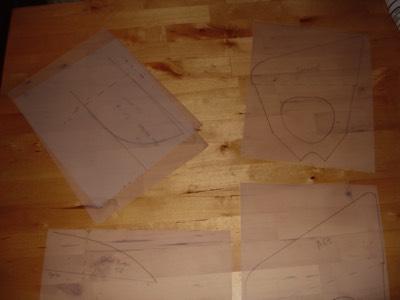

The first step is to trace the full sized patterns for various parts of the rig.

-

7/31/08 - Bulkheads and mast parter pieces are drawn onto a piece of plywood.

-

The bulk heads are rough cut from the ply.

-

The bulkheads are cut down to shape.

-

The bulkheads are laminated together. Altogether, the laminated bulkheads equal about 19 mm. This is 10 more than the plans call for. I am doing this for extra strength for rough weather and for possible installation of nets later on.

-

8/2/08 - The hull panels are drawn out on plywood panels.

-

8/3/08 - The bulkheads are sanded to their final shape.

-

The bulkheads are fiberglassed.

-

This is an upper hull panel being cut out.

-

A finished upper stern hull panel.

-

This is a lower hull panel.

-

The panel is cut and shaped.

-

The bulkheads are ready to be stitched into the boat.

-

The for and aft sections are joined together using a butt joint.

-

The port ama is loosely stitched together.

-

Both amas are stitched up and ready for glue.

-

The port ama with the seams filled with epoxy.

-

8/4/08 - The interiors of the amas are coated with epoxy for waterproofness. Also the seam between the panels was reinforced with fiberglass tape.

-

Sheer clamps are installed.

-

Ledge on the bulkhead for the deck to rest on.

-

Ledge on the bulkhead for the deck to rest on.

-

The starboard ama will have a hybrid strip deck.

-

The starboard ama bow.

-

The second aka is laminated only 3 strips at a time.

-

The deck is finished on the starboard ama.

-

The second aka gets two more strips of wood.

-

The port ama deck is stripped.

-

Since I used old damaged strips for the decks, I had to fill gaps between them with epoxy.

-

8/7/08 - The second aka is fully laminated.

-

8/8/08 - The decks of the amas are sanded smooth.

-

8/9/08 - Wood is cut for the large rudder. I am using a single sized SmartTrack rudder as a core for this one. This way I can still use the ST linkage.

-

8/10/08 - Sheets of plywood and a piece of bloodwood are epoxied together for use as the leeboard.

-

Fiberglass cloth is laid out on the decks of the amas.

-

8/11/08 - The starboard ama deck is fiberglassed.

-

The leeboard is cut out.

-

Both ama decks are 'glassed and fill coated.

-

The extend rudder I am making for the rig. Bronze nails are used to keep the rudder insert in place.

-

The leeboard is rounded and smoothed.

-

8/12/08 - The undersides of the decks are fiberglassed.

-

The rudder and leeboard are sanded and ready for fiberglass.

-

Both are fiberglassed.

-

The decks are epoxied onto the amas.

-

8/14/08 - The aka spacers are assembled.

-

The leeboard gets a fill coat of epoxy on both sideas at once.

-

The amas are sanded smooth. Here you can see the difference pre and post sanding.

-

8/15/08 - The amas are sanded and ready for fiberglass.

-

Glass cloth is laid out.

-

One ama is fiberglassed.

-

The aka spacers are sealed with epoxy.

-

The other ama is fiberglassed.

-

8/16/08 - The mast step is assembled. The hole is irregular because the mast has a rectangular piece at the bottom.

-

The hole is cut for the mast in the mast partner. It is also sealed with epoxy.

-

Both amas get a couple fill coats of epoxy. The white line is not a scratch, it is a discolored section of the plywood.

-

8/17/08 - The aka spacers are attached to the akas.

-

8/18/08 - The bulkheads are reinforced with epoxy fillets. This completes the construction of the amas. I only have to sand and varnish them.

-

The mast partner is attached to the forward aka.

-

The mast step is sealed with epoxy.

-

8/19/08 - The akas and amas are laid out.

-

The akas are trimmed to their proper length.

-

After holes are drilled for bolts in the amas they are put together and laid on the kayak.

-

A hole (gulp!) is cut in the kayak for the mast. This hole will act like a tiny hatch. The hatch lip has a round mast sized hole.

-

The mast is test fit onto the boat.

-

The mast step is installed.

-

The akas are sanded smooth.

-

8/22/08 - The sail rig is set up!

-

All the fittings for the halyards and sheets are installed onto the akas.

-

The akas get the first seal coat of epoxy.

-

9/28/08 - A new rudder that will work with a tiller is being built.

-

The rudder and other pieces are ready for fiberglass.

-

Everything has fiberglass on one side.

-

9/29/08 - The wood for the tiller is fiberglassed.

-

10/3/08 - All the parts are varnished.

-

10/3/08 - All the parts are varnished.

-

12/13/08 - After some sea trials a reinforced carbon fiber end cap was built as a rudder mount.

-

8/26/08 - Everything has been sanded and varnishing has begun. A good view of the leeboard.

-

The amas and akas get a couple of coats of varnish.

-

8/27/08 - The decks of the amas and the lower side of the akas are varnished.

-

8/28/08 - All the pieces are in place.