-

3/22/25 - The deck is ready for fiberglass.

-

Rudder is temporarily mounted.

-

Aft deck is fiberglassed.

-

Forward deck is fiberglassed.

-

3/23/25 - Hatch stiffener and mast partner plate are epoxied in place.

-

Aft mast plate and hatch stiffener.

-

3/24/25 - Hobie mast socket is test fit.

-

Upper bering assembly is test fit.

-

Forward bering assembly.

-

Epoxy fillets are applied.

-

Epoxy fillets are applied.

-

Main hatch is glued together.

-

3/27/25 - Rails for custom sliding hatch are test fit

-

ails for custom sliding hatch are epoxied in place.

-

4/3/25 - Attachment points for forward aka are epoxied in place.

-

Main hatch is fiberglassed.

-

4/4/25 - Inside of hatch is glassed.

-

Carbon fiber reinforcements added.

-

4/5/25 - The oversize bolt hole is filled with epoxy.

-

4/8/25 - Decks are epoxied on the amas.

-

4/10/25 - The ama decks are fiberglassed.

-

4/14/25 - Aka attachment points are epoxied in place.

-

4/17/25 - Deck hardware is laid out.

-

4/18/25 - The custom booms are fiberglassed and the tiller is epoxy sealed.

-

4/22/25 - A frame for solar panel is built.

-

4/23/25 - The hull is partially sanded.

-

4/24/25 - The ceiling of the cabin is painted.

-

Ama decks are fill coated with epoxy.

-

4/25/25 - Solar panel mount is epoxy coated and fiberglassed.

-

4/28/25 - Mizzen outhaul line is routed.

-

Mizzen furling line is routed.

-

Splash guard is test fit.

-

4/29/25 - Solar panel is test fit on holder.

-

4/30/25 - Splash guard is fiberglassed in place.

-

Water diversion pieces are epoxied in place on the amas.

-

5/1/25 - Poles for a cockpit tent are temporaily put in place.

-

Alternate view of the tent poles.

-

Tops for the water diversion pieces are in place.

-

5/5/25 - The decks and part of the cockpit are sanded.

-

5/7/25 - Primer is applied to various parts.

-

Primer is applied to the undersides of the main hatch and solar panel mount.

-

Primer is applied to the hull.

-

5/9/25 - The primer is sanded.

-

Fist coat of paint is applied.

-

Various parts are primed on the other side.

-

Daggerboard and solar panel rack are primed.

-

5/10/25 -Rudder trunk and top of main hatch are primed.

-

Daggerboard and rigger are primed.

-

5/11/25 - First coat of paint.

-

-

5/12/25 - Several coats of paint have been applied.

-

5/13/25 - The deck and cockpit are primed.

-

5/15/25 - The paint pattern on the deck is taped out.

-

One of the amas is sanded.

-

5/16/25 - Main hatch is painted.

-

Areas of white are painted.

-

White sections on forward deck.

-

5/19/25 - The amas are sanded and ready for paint.

-

The akas, spars, and tiller extension are primed.

-

The amas are primed.

-

5/20/25 - The amas are sanded.

-

First coat of white paint.

-

5/21/25 - Cockpit is taped off for nonskid.

-

Two more coats of white.

-

The rigger is painted on one side.

-

Amas, booms, and tiller extension are painted on one side.

-

Tiller handle is painted.

-

5/23/25 - The deck is taped off for red paint.

-

Red accents are applied to main hatch.

-

Aft deck gets red paint.

-

Forward deck red.

-

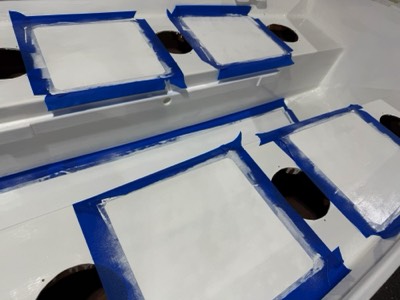

5/23/25 - The ama decks are taped off for white paint.

-

The trailer is assembled.

-

White is added to the ama decks.

-

5/24/25 - Daggerboard and solar panel mount are painted on one side.

-

The rudder is painted on one side.

-

5/27/25 - Red paint is applied to the amas.

-

Several coats of red have been applied.

-

5/28/25 - The tape is removed.

-

Main hatch is finished.

-

Aft deck.

-

5/29/25 - Main hatch closed with acrylic hatch board.

-

5/30/25 - Custom trailer bunks are fiberglassed.

-

Black paint is added to the amas.

-

The rudder retract and lower system is installed.

-

Autopilot plug, camcleat, and cockpit tent hooks are installed.