-

12/2/24 - Douglas Fir stock is ripped to create stringers, sheer clamps, and aka parts.

-

12/3/24 - Aka frames are epoxied together.

-

Hull panels are epoxied to full length.

-

Aka hull panels are epoxied together.

-

12/4/24 - Sheer clamps are epoxied to the #4 panels.

-

Port side panel.

-

Transom is doubled to handle stress of rudder.

-

Sheer clamps are epoxied onto the ama panels.

-

The first two layers of the forward aka are epoxied together.

-

12/6/24 - First two panels and bulkheads are wired together.

-

#2 panels are wired on.

-

#3 panels are wired on.

-

The top layer of the forward aka is epoxied in place.

-

12/8/24 - The #4 panels are wired in place.

-

12/9/24 - The boat is flipped and wires tightenend.

-

Ama bulkheads are fiberglassed.

-

Aft aka is partially laminated.

-

Seams between panels are filled with epoxy.

-

12/10/24 - Amas are being wired together.

-

12/11/24 - Amas are epoxied.

-

Aft aka is epoxied.

-

Hull is flipped and bulkheads are tacked in place.

-

12/13/24 - Parts are laminated together.

-

12/17/24 - Inside faces of the daggerboard trunk and rudder trunk are fiberglassed.

-

Bow storage space is filletted and fiberglass taped.

-

Aft storage is filletted and taped.

-

12/1824 - Cockpit is fiberglassed.

-

12/19/24 - The cabin is fiberglassed.

-

The amas are extended by 12 inches.

-

12/20/24 - The joints between panels and bulkheads are filletted.

-

12/27/24 - One ama is sanded.

-

Second ama is sanded.

-

1/1/25 - The Amas are ready for fiberglass.

-

One ama is satruated with epoxy.

-

1/2/25 - The first step in shaping the akas is done.

-

Knees are epoxied in place.

-

Daggerboard trunk spacers are epoxied in place.

-

Rudder trunk spacer is epoxied in place.

-

Second ama is fiberglassed.

-

1/5/25 - Shaping the akas is progressing.

-

1/6/25 - The insides of the amas are sealed with epoxy.

-

The inside faces of the daggerboard and rudder trunk are given graphite/epoxy coats.

-

Forward deck beams are installed.

-

Aft deck beam is installed.

-

Cockpit seat bulkheads are epoxied in place.

-

1/7/25 - Daggerboard trunk is epoxied together.

-

Akas are covered with carbon fiber.

-

Companionway hatch parts are fiberglassed.

-

Cockpit seat stringers are temporarily installed.

-

1/8/25 - Daggerboard trunk is epoxied in place.

-

Undersides of the akas are covered in carbon fiber.

-

Frame for fuse/switch panel is installed.

-

Cockpit seat sides are epoxied in place.

-

1/9/25 - The switch panel and solar controller are temporarily installed.

-

Tube for wiring is installed.

-

1/10/25 - Half of the hull is sanded.

-

Companionway parts get a coat of epoxy.

-

Edges of the akas are fiberglassed.

-

1/13/25 - The hull is sanded smooth.

-

Fiberglass cloth is laid on the hull.

-

The fiberglass is saturated with epoxy.

-

1/14/25 - The transom is fiberglassed.

-

1/15/25 - Fill coats are applied to ma hulls.

-

Fill coats are applied to the main hull.

-

1/16/25 - Several fill coats are applied.

-

1/17/25 - Main mast step support is epoxied in place.

-

Interior joints are epoxy filleted.

-

Cockpit seats are epoxy filleted.

-

1/22/25 - A box for the house battery is built.

-

Two halves of the rigger are epoxied together.

-

1/24/25 - Deck support stringers are fit.

-

Companionway board supports are epoxied on.

-

1/26/25 - The rigger is ready for fiberglass.

-

One side is fiberglassed.

-

Companionway hatch sides are epoxied in place.

-

1/28/25 - The undersides of the cock pit seat tops are epoxy sealed.

-

Mizzen mast step base is installed.

-

Main mast step base.

-

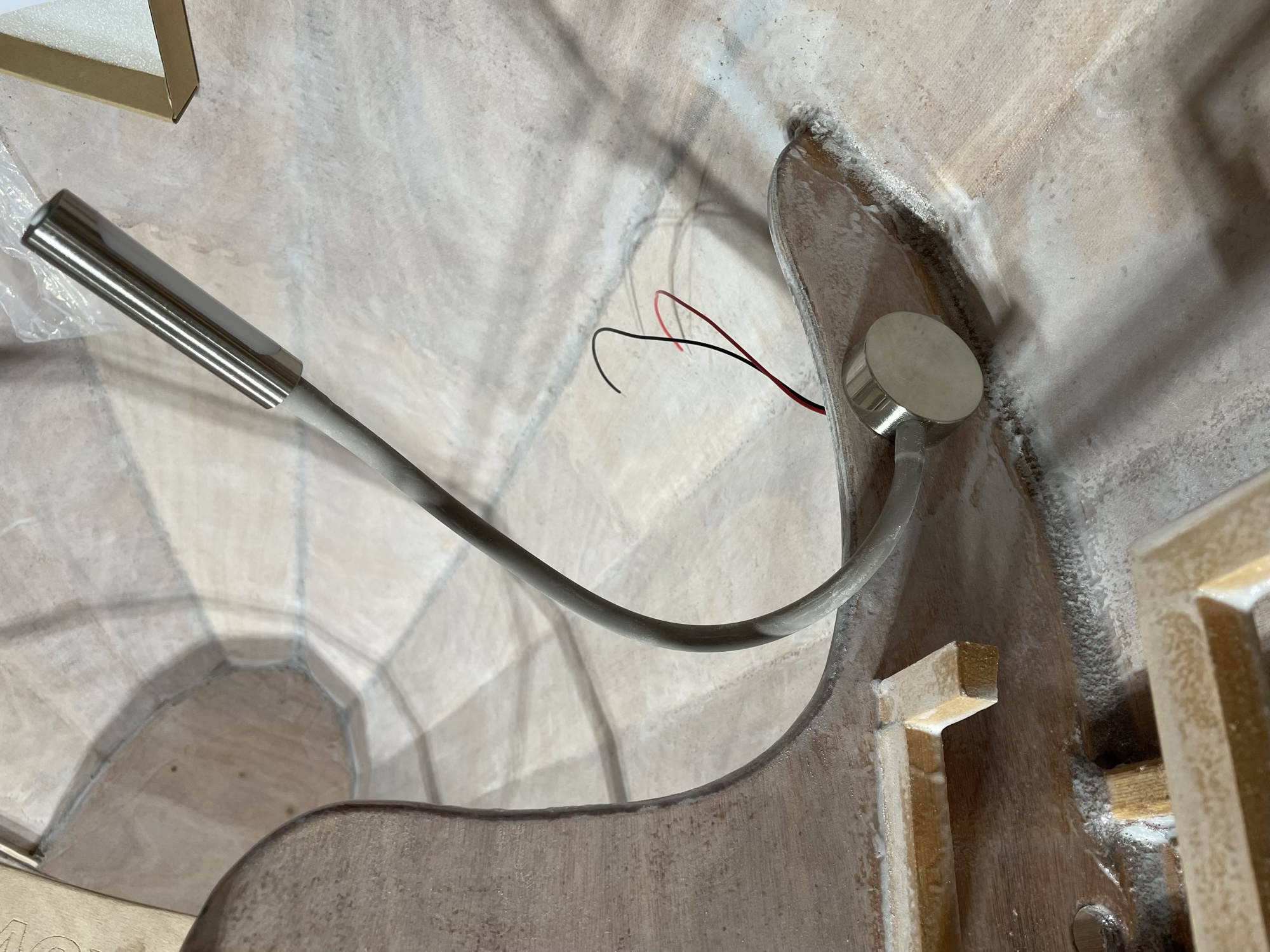

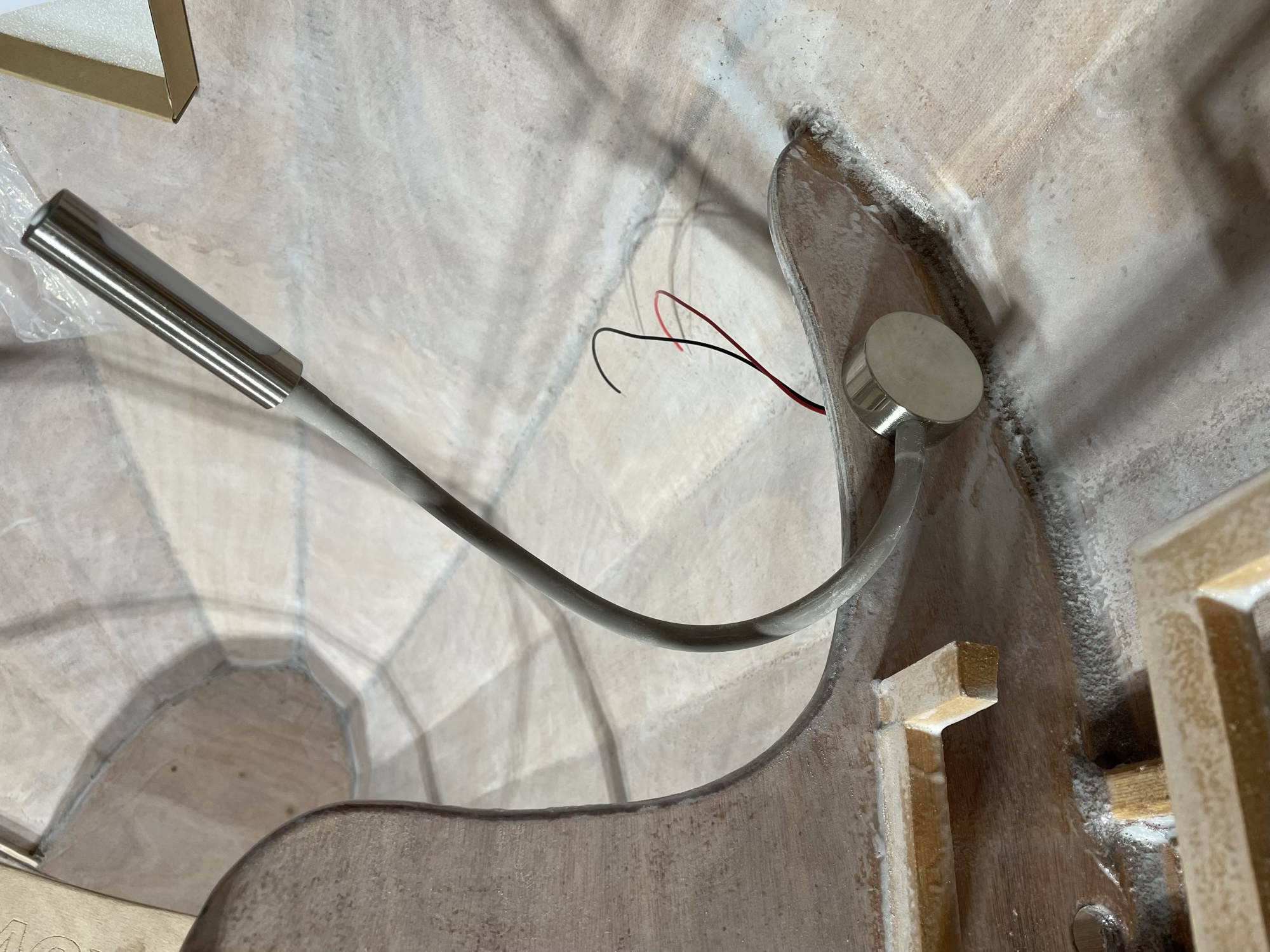

Cabin LED light is temporarily installed.

-

1/30/25 - Washers are inset into the ends of the rigger.

-

The bottom of the rigger is fiberglassed.

-

Undersides of the ama decks are epoxy sealed.

-

Cockpit seat tops are epoxied in place.

-

1/31/25 - Holes for access plates are cut in the cockpit seats.

-

Edges around seats are filleted.

-

Blank for daggerboard is epoxied together.

-

2/4/25 - The daggerboard is shaped.

-

Balanced rudder black is epoxied together.

-

Cockpit is ready for fiberglass.

-

Fiberglass is saturated with epoxy.

-

Rudder and and daggerboard are covered in carbon fiber.

-

Rudder trunk is fiberglassed.

-

2/5/25 - Carbon fiber is trimmed.

-

Aft deck halves are epoxied together.

-

2/6/25 - The foils are covered with an additional layer of fiberglass.

-

2/10/25 - The akas are sanded.

-

Fill coat of epoxy is applied ot one side of the foils.

-

2/11/25 - First coat of primer is applied to cabin.

-

2/12/25 - Second coat of primer is applied.

-

2/13/25 - Silding seat supports are epoxied in.

-

Deck supports are epoxied in place.

-

2/26/25 - The install of the electrical system has begun.

-

3/11/25 - Aka attachment points are installed.

-

Holes in the akas are filled with epoxy to exactly match the bolts.

-

Footrest mount is temporarily set up.

-

3/13/25 - Footrest parts are epoxy sealed.

-

Vent for main hatch is cut out.

-

Rowing rigger bolts are set up.

-

3-17-25 - Footbrace parts and rudder trunk are fiberglassed.

-

3/18/25 - Deck parts are laid out.

-

Forward deck parts are epoxied together.

-

3/19/25 - Underside of forward deck is epoxy sealed.

-

Underside of aft deck is sealed.

-

Awning for main hatch is epoxied in place.

-

3/20/25 - Battery box is epoxied in place.

-

Decks are epoxied in place.

-

Aft deck.