-

10/9/23 - The lumber for the building frame is ready.

-

10/10/23 - The building frame is built.

-

Rails and keelson have been cut and scarfed together.

-

10/11/23 - Transom is epoxied together.

-

The hull panels are epoxied to full length.

-

10/12/23 - The building frames are fixed in place.

-

10/13/23 - Stringers are fixed in place.

-

10/16/23 - The bottom planks are wired together and placed on the frame.

-

All of the planks are fixed in place.

-

Forms for the permanent frames are prepared.

-

10/17/23 - The first frame is laminated.

-

The planks are epoxied together.

-

10/19/23 - The third frame is laminated.

-

The chines are filled with epoxy.

-

10/20/23 - The hull panels are trimmed to match the transom.

-

The frames have all been laminated together.

-

The frames are sanded smooth.

-

The bow is sanded.

-

10/23/23 - Crossbeams are laminated together.

-

10/24/23 - Half the hull and transom is sanded.

-

10/25/23 - The entire hull has been sanded.

-

10/26/23 - Fiberglass is laid on the bottom.

-

The glass is saturated with epoxy.

-

10/27/23 - The hull is given several expoy seal coats.

-

A view from underneath.

-

10/30/23 - The boat is taken off the temporary forms.

-

A custom breasthook is test fit.

-

11/1/23 - Reinforcement panel is epoxied to the transom, and carrying handle tube is epoxied in place.

-

Carrying handle tube is epoxied in place.

-

11/6/23 - The interior is filleted under where fiberglass will lay.

-

Fiberglass cloth is laid on the interior.

-

The glass is epoxy saturated.

-

11/7/23 - The shape of the custom bulkheads is determined.

-

Aft bulkhead shape is cut from carboard.

-

Forward bulkhead.

-

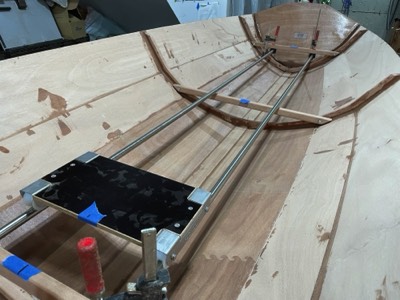

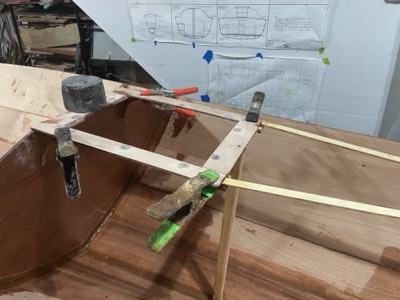

11/8/23 - Frames and sliding seat supports are test fit.

-

Custom bulkheads are fiberglassed on one side.

-

11/10/23 - The frames are epoxied in place.

-

The aft bulkhead is epoxied in place.

-

The forward bulkhead is epoxied in place.

-

11/14/23 - Knees to support a hatch platform are installed.

-

The rails are epoxied in place.

-

11/15/23 - The rails for the sliding seat are test fit.

-

11/25/23 - The aft hatch opening is epoxied in place.

-

Forward hatch opening.

-

11/29/23 - Deck supports are fiberglassed.

-

11/30/23 - Deck supports are reinforced with carbon fiber.

-

12/1/23 - The interior is epoxy sealed.

-

Stern section is epoxy sealed.

-

12/4/23 - Extra reinforcement for the deck is epoxied in place.

-

12/6/23 - A custom queen seat is test fit.

-

12/14/23 - The interior is given an epoxy seal coat.

-

12/15/23 - Gudgeons for a rudder are temporarily mounted.

-

Oarlocks are temporarily mounted.

-

12/18/23 - A custom rudder trunk is half assembled.

-

12/18/23 - The rudder is laminated from three pieces of 6mm plywood.

-

12/19/23 - The inside of the rudder trunk is sealed with epoxy and graphite powder.

-

12/21/23 - The rudder has been shaped and is ready for fiberglass.

-

The sliding seat rail supports and queen seat are epoxy sealed.

-

Fiberglass is saturated with epoxy.

-

1/2/24 - The top of the queen seat is epoxy sealed.

-

Rudder trunk and rudder are fiberglassed.

-

The underside of the rails are filleted.

-

1/4/24 - The rudder trunk is test fit.

-

Hull is partially sanded.

-

The hull has been sanded and is ready for primer.

-

The queen seat is sanded.

-

1/5/24 - The tiller arm is epoxied to the rudder trunk.

-

1/8/24 - The oars are shaped from LVL with carbon blades.

-

First coat of primer is applied to the hull.

-

Rudder is primered on one side.

-

1/10/24 - The carbon blades are epoxied onto the shafts.

-

The undersides of the queen seat and rail supports are varnished.

-

First coat of paint is applied to the hull.

-

1/12/24 - Oars are reinforced with carbon and sealed with epoxy.

-

The second coat of paint is half sanded.

-

1/16/24 - The oars get a red section painted.

-

Final coat of red has been applied.

-

1/18/24 - A seat retention bungee is temporarily installed.

-

The interior is half sanded.

-

Sanding in preparation for varnish is finished.

-

1/19/24 - Heat and bond tape is applied around the deck perimeters.

-

The bow deck dacron is installed.

-

Stern deck dacron.

-

Rudder and trunk are painted.

-

First coat of paint on the bow deck.

-

1/20/24 - Second coat of paint is applied.

-

1/22/24 - Sanding dust is washed from the interior.

-

First coat of varnish on the oars.

-

Flip side of rudder is painted.

-

First coat of varnish on the interior.

-

First coat of varnish on the queen seat top.

-

1/31/24 - A mast for lights and a mirror is installed.