-

10/10/22 - Construction begins!

-

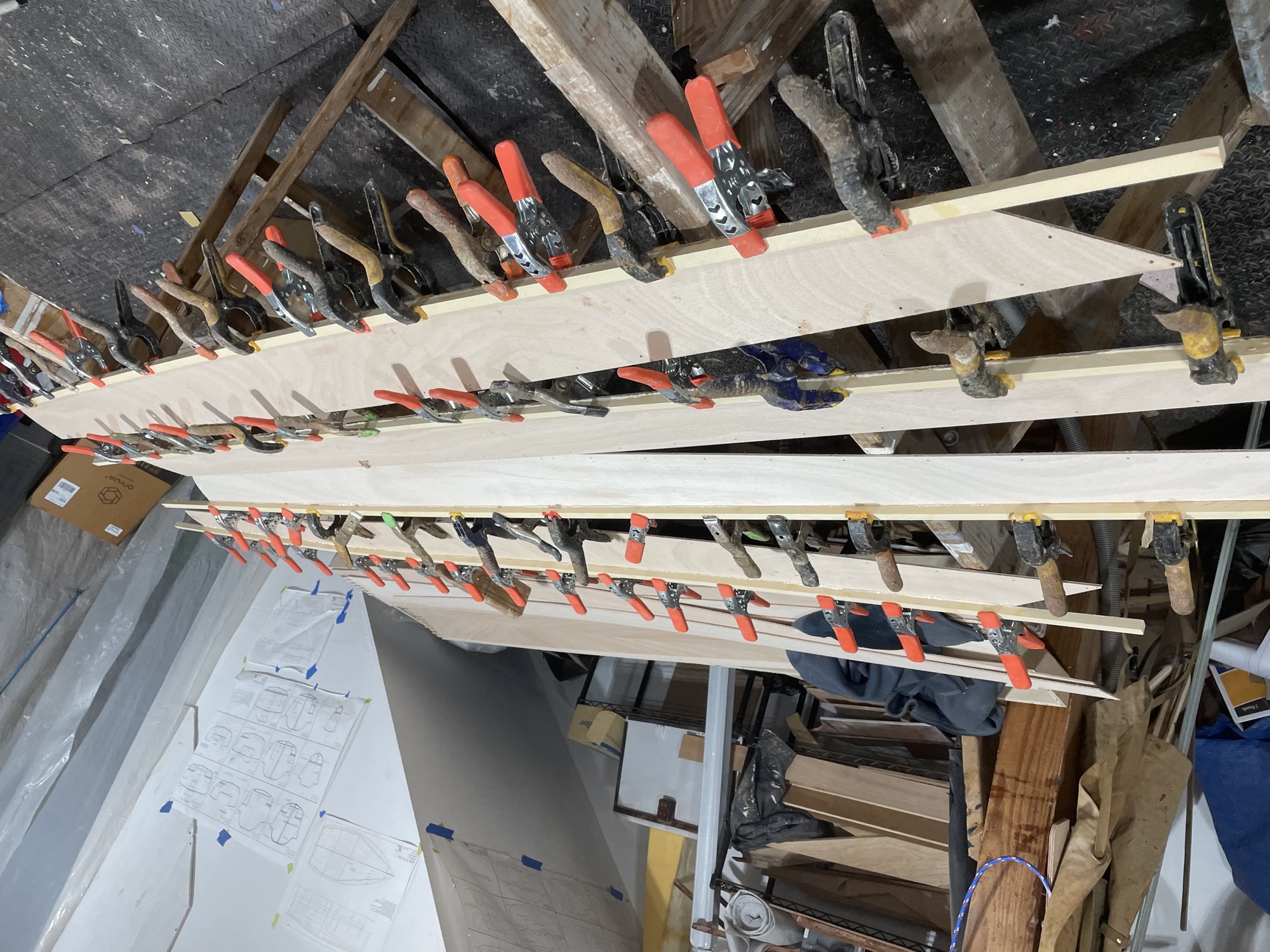

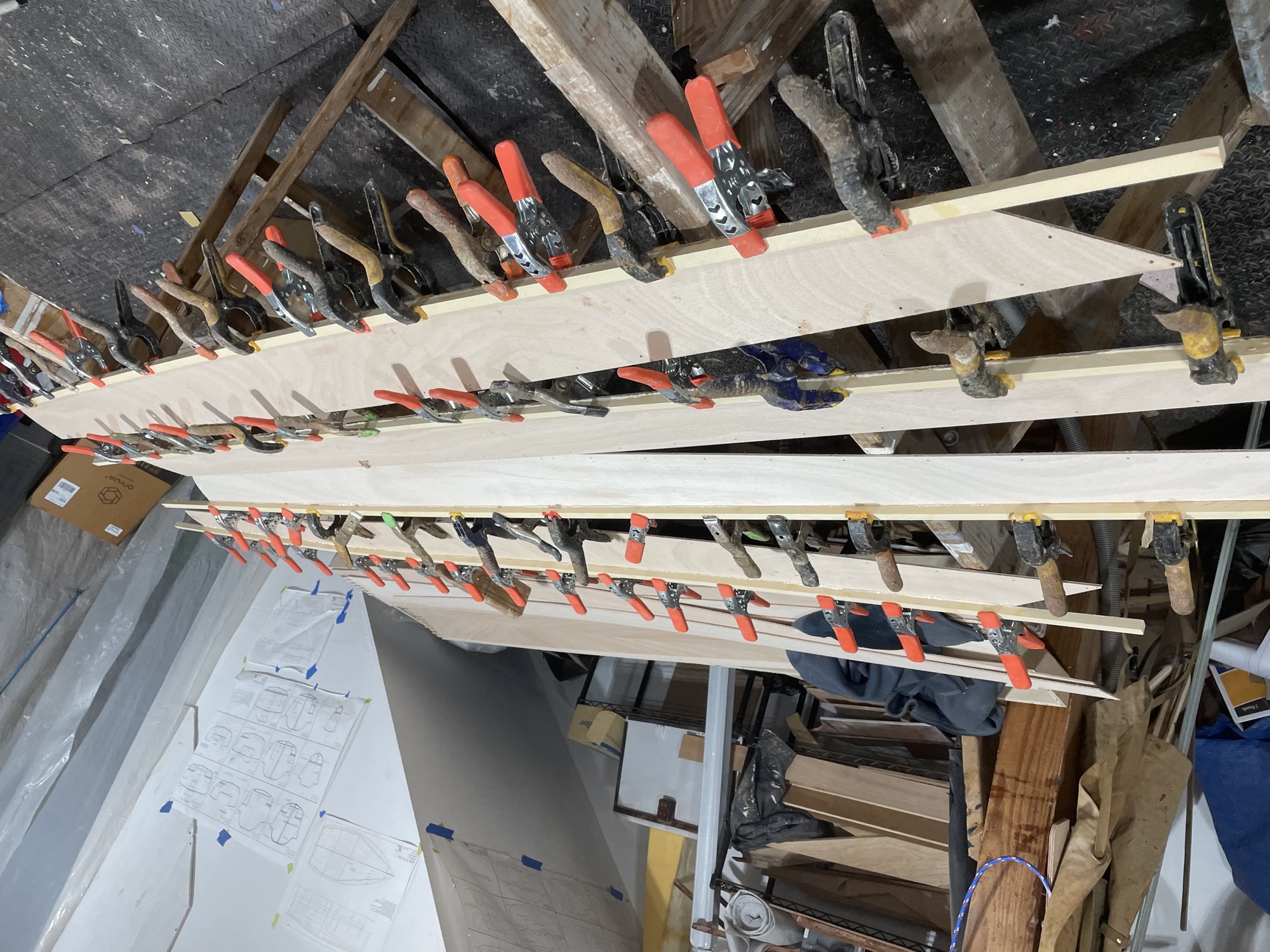

10/11/22 - Sheer clamps are ripped and scarfs are cut.

-

Sheer clamps are epoxied on the Ama #1 panels.

-

10/12/22 - First ama (outrigger float) is wired up.

-

Second ama is wired up.

-

10/13/22 - The seams between panels are filled with epoxy.

-

10/16/22 - The inside of the amas are epoxy sealed. Glue cleats are staged for the tops of the bulkheads.

-

10/18/22 - The ama decks are epoxied in place.

-

10/19/22 - The decks are trimmed.

-

10/20/22 - The aka (crossbeam) cores are epoxied together.

-

10/21/22 - Both amas are sanded.

-

The forward aka is partially epoxied together.

-

Fiberglass cloth is laid on the amas.

-

The fiberglass is epoxy saturated.

-

10/23/22 - The third layer of the forward aka is laminted on.

-

10/24/22 - The aft aka is laminated.

-

The tops of the amas are fiberglassed.

-

The main hull panels are partialled epoxied together.

-

10/26/22 - Hull panels are epoxied to full length.

-

10/27/22 - Sheer clamps are epoxied on the #4 panels.

-

Construction of the amas is complete.

-

10/28/22 - The main hull is mostly wired up.

-

10/29/22 - Wiring the hull is complete.

-

10/31/22 - The hull is flipped and seams are filled with epoxy.

-

11/1/22 - The wires are pulled and the bulkheads are epoxied in place.

-

11/2/22 - The forward section is fiberglass taped.

-

11/3/22 - The aft section is fiberglass taped.

-

11/4/22 - The cockpit area is fiberglassed.

-

Interior cabin area is fiberglassed.

-

11/7/22 - The knees are test fit.

-

Knees are epoxied in place.

-

11/8/22 - The daggerboard trunk is test fit.

-

The trunk is epoxied in place.

-

11/15/22 - The cockpit seat structure is started.

-

Deck beams are epoxied in place.

-

11/16/22 - The cockpit tanks walls are epoxied in place.

-

11/17/22 - The companionway doublers are epoxied in place.

-

11/18/22 - The interior of the cabin is epoxy sealed.

-

Aft storage is sealed.

-

11/22/22 - Deck reinforcement stringers are added.

-

11/25/22 - Cockpit seat covers are trimmed to fit.

-

Underside of the covers is epoxy sealed.

-

11/26/22 - Seat tops are epoxied in place.

-

11/28/22 - The seat tops are trimmed.

-

Mast support tubes are installed.

-

Holes for hatches are cut out.

-

Fiberglass cloth is laid on the seats.

-

The cloth is saturated with epoxy.

-

The companionway hatch surround is epoxied in place.

-

11/29/22 - The rudder trunk is test fit.

-

The cabin interior is sealed with epoxy with fairing filler.

-

11/30/22 - The cockpit is faired.

-

12/1/22 - The cabin is sanded in preparation for primer.

-

12/2/22 - Extra deck stringers are test fit.

-

Shaping of the akas is begun.

-

12/5/22 - The cabin interior is primed.

-

12/6/22 - The undersides of the akas are fiberglassed.

-

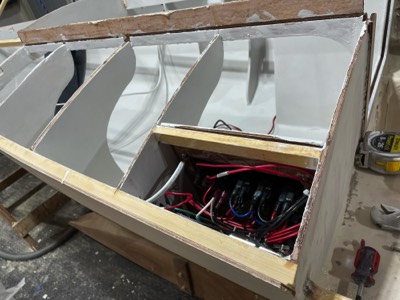

1/2/23 - Most of the electrical wires are installed.

-

View of the panel from the interior.

-

1/3/23 - The aft deck panels are epoxed together.

-

Undersides of the decks are epoxy sealed.

-

1/4/23 - The aka to ama mounts are installed.

-

1/5/23 - the forward deck is epoxied in place.

-

Aft deck is epoxied in place.

-

1/6/23 - The hull is upside down so any gaps between the deck and stringers can be filled.

-

The daggerboard is laminated from strips of Alaskan yellow cedar.

-

1/9/23 - Fiberglass is laid on the sanded hull.

-

The cloth is saturated with epoxy.

-

1/10/23 - An extra strip of fiberglass is laminted on the bow.

-

The self bailer is temporarily installed.

-

Daggerboard slot is cut out.

-

1/11/23 - The daggerboard and rudder have been shaped.

-

The foils are reinforced with unidirectional carbon fiber and fiberglass.

-

The hull is covered with epoxy and fairing filler.

-

1/12/23 - The rowing rigger is fiberglassed.

-

1/17/23 - The hull is partially sanded.

-

Sanding is complete.

-

The boat is flipped and holes are cut for aft hatch and mizzen mast.

-

The underside of the rigger is fiberglassed.

-

The coaming is filleted with epoxy.

-

1/19/23 - The aft deck is fiberglassed.

-

1/20/23 - Riser for aft hatch is epoxied in place.

-

1/21/23 - The forward deck is ready for epoxy.

-

Companionway hatch top is epoxied together.

-

Companionway board is fiberglassed.

-

1/22/23 - The forward deck is fiberglassed.

-

1/23/23 - The rowing rigger mounting blocks are shaped.

-

The outriggers are temporarily put together.

-

1/24/23 - Holes are drilled for navigation light.

-

1/26/23 - The companionway hatch top is fiberglassed.

-

1/30/23 - The frame for the solar panel is started.

-

2/2/23 - Mounts for solar panel rack are epoxied in place.

-

Panel is test fit.

-

Mounts for sliding seat rails are epoxied in place.

-

2/4/23 - The seat tracks are temporarily mounted.

-

2/6/23 - Epoxy fill coats are applied to the deck, cockpit hatch cover, and solar panel rack.

-

2/10/23 - The outrigger parts are partially sanded.

-

Amas and akas are sanded in preparation for paint.

-

2/13/23 - The outrigger parts are painted with primer.

-

Rowing rigger and other parts are primed.

-

The hull is primed.

-

2/14/23 - The first coat of paint is applied to the outriggers.

-

Other parts are painted.

-

First coat for the hull.

-

2/15/23 - The outriggers get another coat of paint.

-

2/20/23 - The amas are taped for deck paint and the akas are given the final coat of satin paint.

-

The cockpit is primed.

-

2/21/23 - First coat of paint is applied to cockpit.

-

2/22/23 - Second coat of paint.

-

2/23/23 - Areas are taped off for nonskid.

-

Paint and non-skid is added.

-

Final coat of paint is applied.

-

2/24/23 - Lines for red accent stripes are taped off.

-

First coat of red accent on the amas.

-

First coat of red on the main hull.

-

Aft section.

-

2/26/23 - After several coats of red the tape is pulled.

-

Satin black is added to aka mounts.

-

2/27/23 - First coat of varnish.

-

First varnish coat on main hull.

-

2/28/23 - Several coats of varnish have been applied.

-

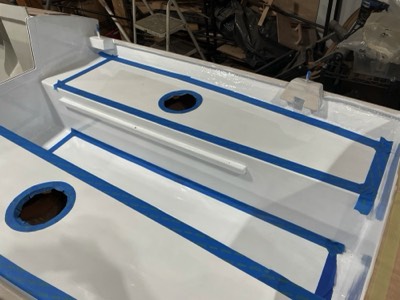

3/1/23 - The finished fuse panel.

-

Aft hatch, mast step, and anchor/all around nav light are installed.

-

Rudder is mounted.

-

Solar charging cables are installed.

-

Forward deck hardware is installed.

-

3/2/23 - Hatch straps are installed.

-

3/5/23 - All the components are assembled.