-

10/10/22 - The hull panels are laid out.

-

10/13/22 - Fiberglass is laid on hull panels.

-

The glass is saturated with epoxy.

-

10/17/22 - The #3 panels and various parts are fiberglassed.

-

10/19/22 - The bottom panel and #1 panels are wired in place.

-

10/20/22 - #2 panels are wired in place.

-

#3 panels are in place.

-

Rails are epoxied in place.

-

10/21/22 - The boat is flipped and the seams between panels are filled.

-

10/24/22 - The transom inwale is epoxied in place.

-

The inner stem is epoxied in place.

-

10/25/22 - The aft seat bulkhead is filleted.

-

Mast partners are epoxied onto the forward bulkhead.

-

Reinforcement plates are epoxied onto the take-apart bulkhead.

-

10/26/22 - Take - apart bulkheads are fiberglassed.

-

10/31/22 - The seams between panels are filleted and covered with fiberglass tape.

-

The take apart bulkheads are prepared to be installed.

-

11/1/22 - The forward seat cleats are epoxied in place.

-

Take apart bulkheads are epoxied in place.

-

Bow is shaped and towing fitting is epoxied in.

-

11/2/22 - Underside of the deck is fiberglass taped.

-

Knees are epoxied in place.

-

11/3/22 - Underside of the deck is reinforced.

-

Daggerboard trunk is epoxied in place.

-

Aft seat tank walls are epoxied in place.

-

11/4/22 - Aft seat tank tops are epoxied in place.

-

11/7/22 - The aft seat is sanded.

-

The seat edges are fiberglassed.

-

The bulkhead knees are glassed.

-

11/13/22 - The underside of the deck is epoxy sealed.

-

11/14/2 - Time to cut a perfectly good boat in half!

-

The boat is two boats now!

-

The aft edges of the foils are epoxy reinforced.

-

11/15/22 - The deck is epoxied in place.

-

11/16/22 - The forward deck is filletted.

-

11/25/22 - Deck is given an epoxy fill coat.

-

Foils are fiberglassed.

-

11/26/22 - Breasthook is epoxied in.

-

11/18/22 - The top edge of the gunwale is ready for fiberglass.

-

Aft section gunwale is glassed.

-

11/30/22 - The hulls are sanded smooth.

-

Rudder gudgeons and pintles are test mounted.

-

12/1/22 - Fiberglass is laid on the hulls.

-

The glass is saturatred with epoxy.

-

12/2/2 - The bottom is ready for fiberglass.

-

12/4/22 - The skeg is epoxied and fiberglassed in place.

-

12/5/22 - The hull is coated with epoxy thickened with fairing compound.

-

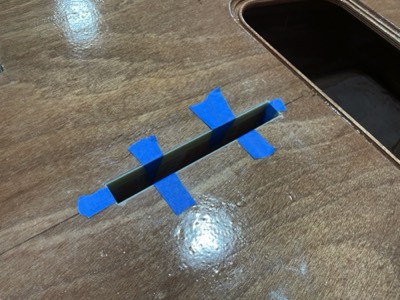

12/6/22 - Fiberglass rub strips are fitted in the daggerboard slot.

-

The rail is fiberglassed.

-

Forward section.

-

Underside of the daggerboard slot.

-

1/3/23 - Half the the hull is sanded.

-

1/9/23 - The alignment clips are temporarily mounted.

-

1/12/23 - A spacer for an outboard is epoxied in place.

-

1/17/23 - The interior is sanded and ready for varnish.

-

1/19/23 - Sanding dust is washed off.

-

The interior is varnished.

-

Extra parts are varnished.

-

1/24/23 - First coat of Interlux Perfection Off-white is applied.

-

Foils are painted on one side.

-

1/27/23 - Locations for footbraces are taped off.

-

2/1/23 - Gaskets for the hatch and daggerboard slot plug are installed.

-

2/6/23 - The outboard is fit one last time and the boat is finished!