-

4/9/20 - The build begins by unpacking the kit.

-

4/10/20 - The hull panels are laid out.

-

4/16/20 - Fiberglass is laid on the hull panels.

-

4/17/20 - The cloth is saturated with epoxy.

-

4/20/20 - The last two hull panels and two bulkheads are ready for fiberglass.

-

The fiberglass is saturated with epoxy.

-

4/22/20 - The hull panels are sanded.

-

4/23/20 - Several parts are given a seal coat of epoxy.

-

The rails are epoxied together.

-

4/26/20 - The bottom panel and #1 panels are wired into place.

-

4/27/20 - The #2 panels are wired into place.

-

The #3 panels are in place.

-

The rails are epoxied in place.

-

4/28/20 - The seams are filled with thickened epoxy.

-

4/29/20 - The inner stem is epoxied in place.

-

Wires are pulled from the hull.

-

Transom reinforcement is epoxied in place.

-

4/30/20 - A second reinforcement piece is epoxied in place.

-

5/7/20 - The bow bulkhead and mast step are given an epoxy fillet.

-

The transom and aft seat bulkhead are fileted with epoxy.

-

5/7/20 - The temporary section of the aft seat bulkhead is cut out.

-

5/11/20 - The underside of the rails are given an epoxy fillet.

-

Take-apart bulkheads are reinforced.

-

Take-apart bulkheads are fiberglassed.

-

5/13/20 - The bow is shaped.

-

Half of the seams are filleted with thickened epoxy.

-

5/14/20 - The other half of the boat is filleted.

-

The take-apart bulkheads are sanded.

-

Spacer strips are stuck on the bulkheads.

-

5/15/20 - The take-apart bulkhead is epoxied in place.

-

5/18/20 - Gussests are epoxied in place.

-

Rudder trunk parts are fiberglassed.

-

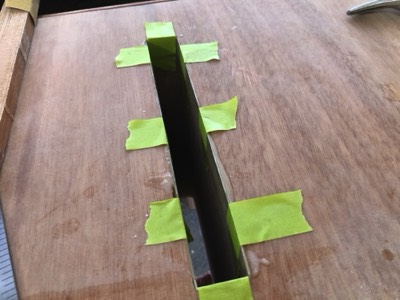

5/19/20 - The daggerboard trunk is assembled.

-

The take-apart bulkhead is filleted.

-

5/20/20 - The daggerboard trunk is assembled.

-

5/21/20 - The daggerboard trunk is sealed with epoxy and the rudder trunk is assembled.

-

Fiberglass tape is cut from a roll.

-

Glass tape and peel ply are ready to reinforce the seams between panels.

-

5/22/20 - The daggerboard trunk is epoxied in place.

-

The fiberglass tape is saturated with epoxy and covered with peel ply.

-

5/23/20 - The take-apart gussests are sanded smooth.

-

5/24/20 - Gussets are fiberglassed.

-

The aft seat pieces are fiberglassed.

-

5/26/20 - The aft seat tops are taped in place in order to put in a blind fillet.

-

The daggerboard slot is cut out.

-

Sheer clamps are epoxied to the deck halves.

-

5/27/20 - The mast partner is epoxied in place.

-

The aft seat walls are epoxied in place.

-

The deck halves are epoxied together.

-

5/28/20 - The aft seat tops are epoxied in place.

-

5/29/20 - The aft seats are given an epoxy fillet.

-

6/1/20 - The underside of the deck is sealed with epoxy.

-

Take-apart bolts are epoxied in place.

-

The edges of the seats are fiberglassed.

-

The edges of the foils are created with thickened epoxy.

-

The hatch cover reinforcement is epoxied in place.

-

6/2/20 - The hatch lip is epoxied in place.

-

The foils are fiberglassed.

-

6/3/20 - The boat is sawed in half.

-

The boat halves are separated.

-

Take apart bolt sockets are filled with epoxy.

-

The deck is fiberglassed.

-

6/5/20 - The deck is given a fill coat of epoxy.

-

6/11/20 - Edges are given an epoxy reinforcement.

-

Close up.

-

6/12/20 - The mast tube is epoxied in place.

-

6/14/20 - The deck is epoxied in place.

-

6/15/20 - The deck to hull joint is filleted with epoxy.

-

6/18/20 - The aft section is sanded smooth.

-

Forward section is sanded.

-

Rudder is temporarily mounted on the transom.

-

6 oz. fiberglass is laid on the hulls.

-

The glass is saturated with epoxy.

-

Various pieces are given epoxy fill coats.

-

6/19/20 - 8 oz. fiberglass is laid on the hull.

-

6/22/20 - The aft section is glassed.

-

Forward section.

-

6/23/20 - Several fill coats of epoxy are applied to the forward section.

-

Several fill coats of epoxy are applied to the aft section.

-

6/24/20 - The transom is fiberglassed.

-

Forward take apart bulkhead is fiberglassed.

-

6/25//20 - The skeg is epoxied in place.

-

6/27/20 - The skeg is fiberglassed.

-

6/28/20 - The top edges of the rails are ready for fiberglass.

-

The glass is saturated with epoxy.

-

7/1/20 - The sides of the rails are covered with fiberglass.

-

Forward section.

-

Bits and pieces are sealed with epoxy.

-

7/6/20 - Half of the aft section is sanded.

-

Protective fiberglass strips are epoxied into the top of the daggerboard trunk.

-

7/7/20 - The aft section is sanded.

-

The forward section is sanded.

-

8/10/20 - The first coat of primer is applied.

-

Bow section.

-

8/11/20 - The primer is sanded.

-

8/11/20 - The first coat of paint is on the hull.

-

8/18/20 - Several coats of paint later.

-

8/19/20 - The alignment clips are mounted.

-

8/30/20 - Sanding dust is washed from the interior.

-

8/31/20 - First coat of varnish is applied.

-

Parts and pieces are varnished.

-

9/2/20 - Several coats of varnish have been applied.

-

9/4/20 - Footbrace locations are marked.

-

Footbraces are epoxied in place.

-

Oarlock risers are epoxied in place.

-

9/6/20 - The rudder is mounted.

-

The rubber bumper strip is glued in place.